عرض الكل

عرض الكل

أداء موثوق في ثني الحديد بجودة صناعية تدوم طويلاً.

ضمان المنتجات

6 Months

ضمان المنتجات

6 Months

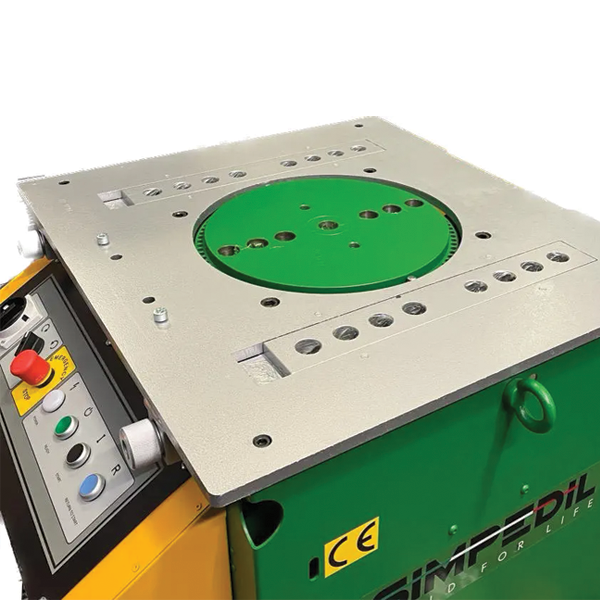

مصمم لتحمّل بيئات العمل الصناعية القاسية، يجمع SIMPEDIL P38 EVO بين الحِرفية الإيطالية الدقيقة وقدرة الثني القوية حتى قطر 46 مم مع محرك 3 كيلوواط (4 حصان)، لتلبية متطلبات التشغيل المتواصل بأقصى درجات الاعتمادية. يوفّر قرص الدوران الكبير بقطر 395 مم مع علبة تروس من الحديد الزهري ثباتاً هيكلياً عالياً ودقة في الزوايا الكبيرة مع تقليل الاهتزاز، حتى عند ثني الحديد بشكل مزدوج أو ثلاثي. كما يُتيح معدل إنتاج يصل إلى 5 ثنيات في الدقيقة، مما يعزّز من كفاءة الإنجاز في المشاريع الضخمة. ويمنح نظام التحكم الثنائي ودواسة القدم المريحة تحكمًا كاملاً دون إجهاد، مع دعم أنظمة حماية الطوارئ وهيكل معزز ومنصات دعم ممتدة، لتقديم أداء مثالي في مواقع الإنشاءات والمسابك ومصانع تشكيل الحديد. استعرض المجموعة الكاملة من [مقصات حديد التسليح] و[ثنايات حديد التسليح].

• علبة تروس من حديد الزهر الكروي: هيكل بدون لحامات يمنح أعلى درجات المتانة والثبات ومقاومة الصدمات في المواقع الصعبة

• قرص دوار بقطر 395 مم: يدعم زوايا ثني واسعة وقضبان ذات أقطار كبيرة بدون الحاجة لمرفقات إضافية

• سرعة ثني عالية: ينفذ حتى 9 ثنيات في الدقيقة لتعزيز الإنتاجية في المشاريع ذات المتطلبات المرتفعة

• نظام ثني باتجاهين: دوران مع وعكس عقارب الساعة لتشكيل الحلقات، الزوايا، الإطارات، والانحناءات المعقدة

• دواسة قدم + نظام أمان متكامل: تشغيل بدون استخدام اليدين من الجهتين، مع زر طوارئ، حماية من التحميل الزائد، وغطاء حماية للدواسة

• هيكل نقل ثقيل الدعم: يدعم الثني المزدوج ويضمن دقة التكرار وسلاسة الأداء في العمليات الصناعية

• ميزات أمان مخصصة للمستخدم: تشمل واقيات حماية، مفتاح أمان عند فتح الغطاء، ونظام يمنع التشغيل غير المقصود

• منصة دعم للسيخ الطويل: تدعم القضبان الطويلة لتوفير ثني مستقيم ودقيق بأقل تدخل يدوي

• شاسيه وهيكل معزز: مصمم لتحمل ظروف العمل القاسية بعمر تشغيلي طويل وصيانة منخفضة

• مشاريع البناء والبنية التحتية

• ورش ومصانع تشكيل حديد التسليح

• إنتاج الحلقات والزوايا والإطارات المعدنية

• تطبيقات الجسور والأنفاق وأعمال الأساسات

| الموديل | P38 EVO |

|---|---|

| قدرة المحرك | 3 كيلوواط / 4 حصان |

| الجهد الكهربائي | 380 فولت / 3 فاز / 60 هرتز |

| السعة (حديد عادي – 65 كجم/مم²) | |

| قضيب مفرد | 34 ملم |

| قضيب مزدوج | 26 ملم |

| ثلاثي القضبان | 20 ملم |

| السعة (حديد عالي الشد – 85 كجم/مم²) | |

| قضيب مفرد | 32 ملم |

| قضيب مزدوج | 24 ملم |

| ثلاثي القضبان | 18 ملم |

| حجم القرص الدوار | 395 ملم |

| سعة الشحم | 5 كجم |

| الأبعاد | 860×900×850 ملم |

| الوزن | 320 كجم |

| بلد المنشأ | إيطاليا |

No videos available