عرض الكل

عرض الكل

طعاجة حديد تسليح

ضمان المنتجات

12 Months

ضمان المنتجات

12 Months

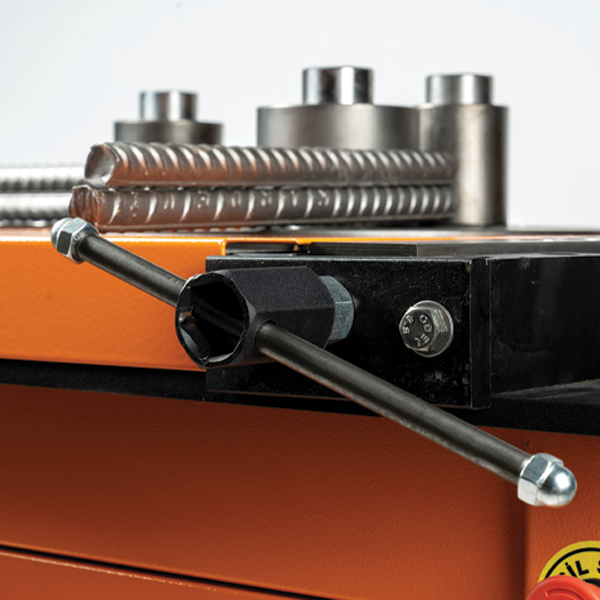

تم تطوير ثناية الحديد GMS B50 لتناسب أصعب مواقع البناء التي تتطلب أداءً فائقًا من حيث القوة والدقة والسلامة. بفضل محركها القوي بقدرة 5.5 كيلو واط (7.5 حصان) ونظامها الذكي للثني في كلا الاتجاهين (يمين ويسار)، توفر هذه الماكينة تحكمًا عاليًا في تشكيل الأسياخ والحديد الدائري حتى قطر 50 ملم، مع تقليل الجهد اليدوي وزيادة كفاءة العمل. وتتميز الماكينة بـ ذاكرة برمجة للزوايا تتيح تخزين ما يصل إلى 9 زوايا مسبقة الإعداد، ما يجعلها مثالية للإنتاج المتكرر والسريع، خصوصًا عند تشكيل الحلقات، الكانات، واللولبيات المعقدة.

صُممت لتحمل العمل الشاق طويل الأمد، حيث تتمتع بهيكل معدني مطلي مقاوم للتآكل، وتروس عالية العزم، ومكونات فولاذية معالجة حراريًا تمنحها صلابة استثنائية ومتانة عالية في الظروف القاسية. كما يساهم التصميم الصناعي المتوازن في تقليل الاهتزازات وإطالة عمر الماكينة وملحقاتها.

لضمان أعلى مستويات الأمان للمشغل، تم تزويدها بنظام حماية ذكي يشمل زر الإيقاف الطارئ، دواسة القدم، وزر الإيقاف السريع، إضافةً إلى لوحة تحكم ذكية وسهلة الاستخدام، مع إلكترونيات صيانة مبسطة تقلل تكاليف الأعطال. لأعمال حديد التسليح، استعرض [طعاجات حديد التسليح] و[مقصات حديد التسليح].

• ثني في الاتجاهين: دوران يمين ويسار يدوي وآلي لتشكيل الكانات والحلقات والانحناءات بزوايا متنوعة

• أتمتة دقيقة للثني: نظام ميكانيكي وكهربائي يوفّر أداءً سريعًا ودقيقًا ومتكررًا في كل دورة

• زوايا قابلة للبرمجة: إمكانية حفظ حتى 9 زوايا مختلفة تناسب إنتاج المهام المتكررة

• نظام تروس عالي العزم: يوفر عزمًا قويًا في هيكل مضغوط قادر على تحمل الاستخدام الشاق

• دقة في ضبط الدبابيس: يضمن توافقًا مثاليًا مع الانحناءات الخاصة بالمفاصل والخطافات والزوايا

• هيكل مقاوم للتآكل: طلاء إلكتروستاتيكي يحمي من الصدأ والتآكل في مواقع العمل القاسية

• متانة هندسية عالية: مكوّنات فولاذية معالجة حراريًا لتحمل الضغط والعمل الطويل

• نظام أمان ذكي: زر طوارئ، دواسة قدم، وآلية توقف سريع لضمان سلامة المشغل

• إلكترونيات سهلة الصيانة: بطاقات تحكم إلكترونية بتصميم GMS تتيح التشخيص السريع وخفض تكلفة الصيانة

• هيكل صناعي متوازن: توزيع وزن مدروس لتقليل الاهتزازات وزيادة ثبات الماكينة أثناء التشغيل

• توافق مع أنواع متعددة من الأسياخ: يمكن استخدامه مع الأسياخ المضلعة أو الملساء بسهولة

| الموديل | B50 |

|---|---|

| قدرة المحرك | 5.5 كيلوواط / 7.5 حصان |

| الجهد الكهربائي | 380 فولت – ثلاثي الطور |

| التردد | 60 هرتز |

| السعة (45 كجم/مم²) | 50 × 1 / 32 × 2 |

| السعة (65 كجم/مم²) | 45 × 1 / 30 × 2 |

| السعة (85 كجم/مم²) | 36 × 1 / 28 × 2 |

| الدوران | مزدوج الاتجاه (يمين / يسار) |

| الأبعاد | 860 × 1190 × 890 ملم |

| الوزن | 457 كجم |

| بلد المنشأ | تركيا |