See all Simpedil products

See all Simpedil products

Steel Bar Bender

Built with authentic Italian mechanical craftsmanship, the SIMPEDIL P38 EVO delivers the durability, torque, and precision required for demanding rebar bending environments. Engineered for continuous-duty construction sites and prefabrication facilities, it shapes reinforcement bars up to 34mm with consistent bending accuracy thanks to its 3kW (4HP) industrial motor powered by a stable 380V 3-phase system.

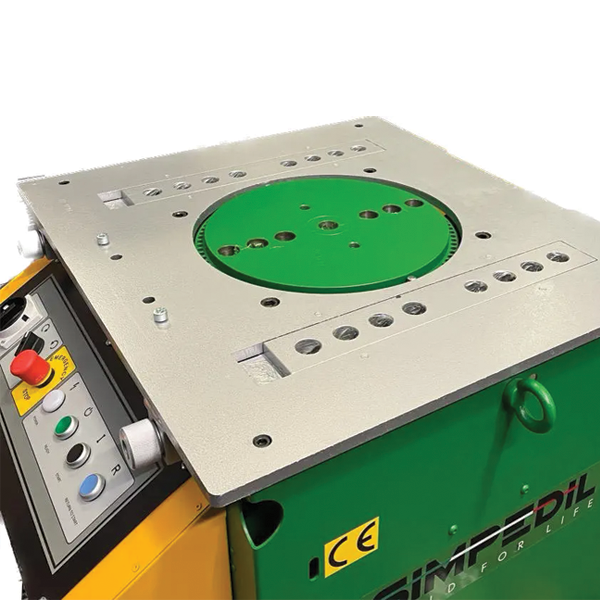

The P38 EVO’s spheroidal cast-iron gearbox enhances structural rigidity and eliminates lubrication leakage, maintaining optimal performance under high mechanical stress. Its widened 395mm rotary plate increases bending stability and allows operators to execute larger-radius bends without auxiliary attachments—ideal for foundations, slab reinforcement, cages, hooks, spirals, and structural steelwork.

A reinforced frame, thermal overload protection, and expanded carriage layout enable the machine to sustain intense operational loads while supporting double bends and rapid repetition cycles. The dual-direction mechanism paired with a responsive ergonomic foot pedal gives operators full control without manual strain, reducing fatigue during long shifts. Safety systems—including emergency stop, overload security, pedal guards, and anti-activation features ensure dependable operation in high-pressure jobsite conditions.

Whether your workflow involves stirrups, ties, framing bars, or complex custom shapes, the P38 EVO delivers repeatable, high-torque bending built to withstand years of professional use.

Discover more industrial-grade solutions inside our [Bar Bender Machines] and [Bar Cutting Machines], along with essential jobsite machinery under [Construction Equipment] for high-performance steel processing and heavy-duty onsite operations.

• Spheroidal Cast Iron Gearbox: Weld-free housing ensures maximum rigidity, sealing quality, and resistance to mechanical shock in tough jobsite conditions.

• 395mm Rotary Plate: Allows wide-angle bends and supports large-diameter bars without the need for extra attachments.

• High Bending Speed: Achieves up to 9 bends per minute, boosting productivity on high-demand construction sites.

• Dual-Direction Bending: Clockwise and counterclockwise rotation for stiDrrups, spirals, hooks, frames, and complex bend shapes.

• Ergonomic Foot Pedal + Safety System: Hands-free operation from both sides, paired with emergency stop, overload protection, and secure pedal guard.

• Heavy-Duty Carriage Structure: Extended support enables double bends, precise repetitions, and continuous industrial shaping.

• User-Centric Safety Features: Includes protective guards, internal safety door switch, and anti-activation mechanisms for safer operation.

• Rebar bending on construction sites and prefab factories

• Producing spirals, stirrups, frames, U-bars, hooks, and custom angled segments

• Suitable for up to 34mm standard bars and 32mm high-tensile rebar

• Bar Bender Machine

• Foot Pedal Control

• Bending Pin Set & Accessories

• User Manual

| Model | P38 EVO |

|---|---|

| Motor Power | 3kW / 4HP |

| Voltage | 380V / 3 Phase / 60Hz |

| Capacity (Standard Rebar – 65kg/mm²) | |

| Single Bar | 34mm |

| Double Bars | 26mm |

| Triple Bars | 20mm |

| Capacity (High Tensile – 85kg/mm²) | |

| Single Bar | 32mm |

| Double Bars | 24mm |

| Triple Bars | 18mm |

| Rotary Plate Size | 395mm |

| Grease Capacity | 5kg |

| Dimensions | 860×900×850 mm |

| Weight | 320kg |

| Country of Origin | Italy |