فريزة الألمنيوم يلماز FR221S

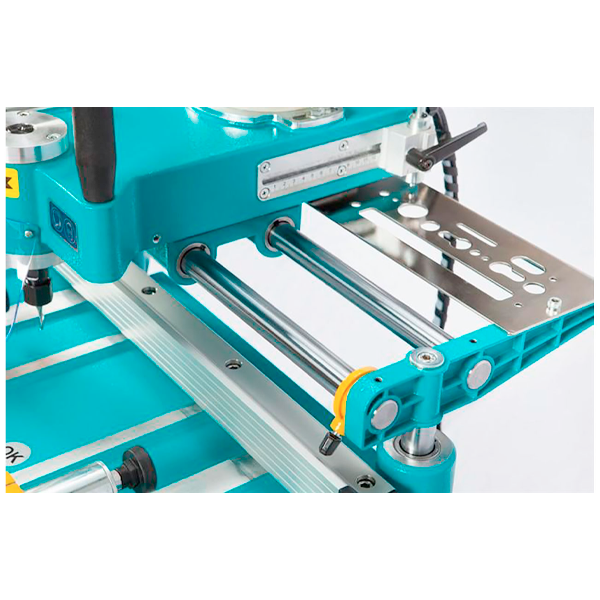

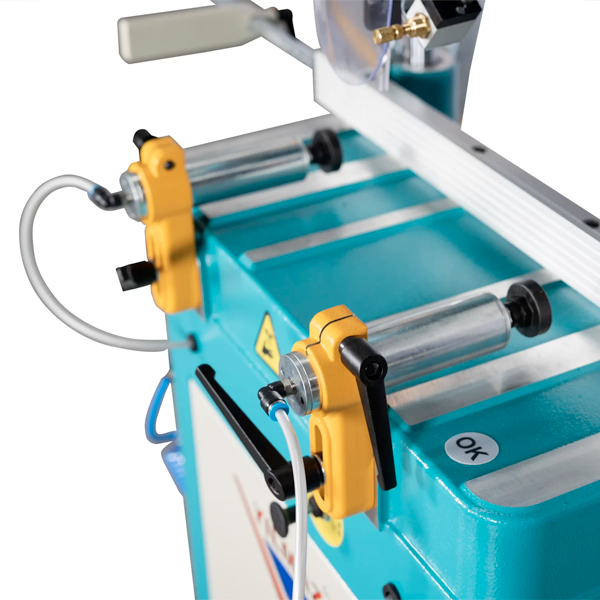

تقدم فريزة الألمنيوم من يلماز حلاً احترافيًا لتفريز مقاطع الألمنيوم وPVC بدقة عالية وسرعة ثابتة في بيئات التصنيع المتخصصة. تعمل بمحرك قوي بقدرة 0.75 حصان (550 واط) بسرعة 14,000 دورة/دقيقة لتوفير نتائج تفريز نظيفة وسلسة حتى على المقاطع الرقيقة بسماكة تصل إلى 3 مم. يعتمد الجهاز على نظام نسخ هوائي بنسبة 1:1 يضمن تكرارًا دقيقًا للقوالب والأشكال المعقدة بثبات عالٍ. كما توفر مقابض التحكم المزدوجة المحاور تحكمًا مستقلاً في عمق النزول واتجاه التفريز لزيادة الدقة أثناء التشغيل. ويعزز الهيكل المصنوع من الحديد الزهر ثبات الماكينة، بينما يساهم نظام التبريد بالرذاذ المدمج في تقليل الحرارة وإطالة عمر أداة القطع خلال الاستخدام المتواصل.

يدعم الجهاز نظام تثبيت قابل للتعديل ليتناسب مع مقاطع بعرض من 10 مم حتى 130 مم، مع قاعدة مدمجة وثابتة مناسبة للتركيب على طاولة العمل. كما يأتي مزودًا بـ مسدس هواء لتنظيف الرايش للحفاظ على بيئة عمل نظيفة، إضافة إلى تصميم يسمح بتغيير أداة التفريز بسهولة لتقليل وقت التوقف وزيادة الإنتاجية. ويمكنك استعراض التشكيلة الكاملة ضمن فئة [مكائن تفريز الألمنيوم] و[مناشير قص الألمنيوم].

الميزات والفوائد الرئيسية:

• نظام نسخ هوائي: تفريز دقيق بنسبة 1:1 باستخدام القوالب.

• محرك عالي السرعة (550 واط / 0.75 حصان): سرعة 14,000 دورة/دقيقة يعمل على 230 فولت أحادي.

• قدرة تفريز المقاطع الرقيقة: يعالج الألمنيوم حتى سماكة 3 مم بدقة عالية.

• مقابض تحكم مزدوجة المحاور: تحكم مستقل في عمق واتجاه التفريز.

• نظام تبريد بالرذاذ: يقلل الحرارة ويطيل عمر أداة القطع.

• محامل مقاومة للتآكل: تضمن حركة سلسة وأداء طويل الأمد.

• تثبيت قابل للتعديل: يدعم مقاطع بعرض من 10 مم إلى 130 مم.

• هيكل مدمج وثابت: مناسب للتركيب الآمن على طاولة العمل.

• تنظيف سريع: مسدس هواء مدمج لإزالة الرايش والغبار.

• تغيير سهل للأداة: تصميم يتيح استبدال الريشة بسرعة.

الاستخدامات المثالية:

• فتحات الأقفال والمقابض في أبواب الألمنيوم وPVC

• حفر المفصلات باستخدام قوالب دقيقة

• تصنيع اللوحات والواجهات من الألمنيوم والبلاستيك

• إنتاج الواجهات والإطارات والفواصل

• تصنيع الأسوار والدرابزينات من مقاطع غير حديدية

• تفريز القوالب بكميات كبيرة في خطوط إنتاج النوافذ

عرض الكل

عرض الكل

ضمان المنتجات

ضمان المنتجات